Forming, and Bending, THe Press-Brake Operation

PRESS BRAKE CENTER

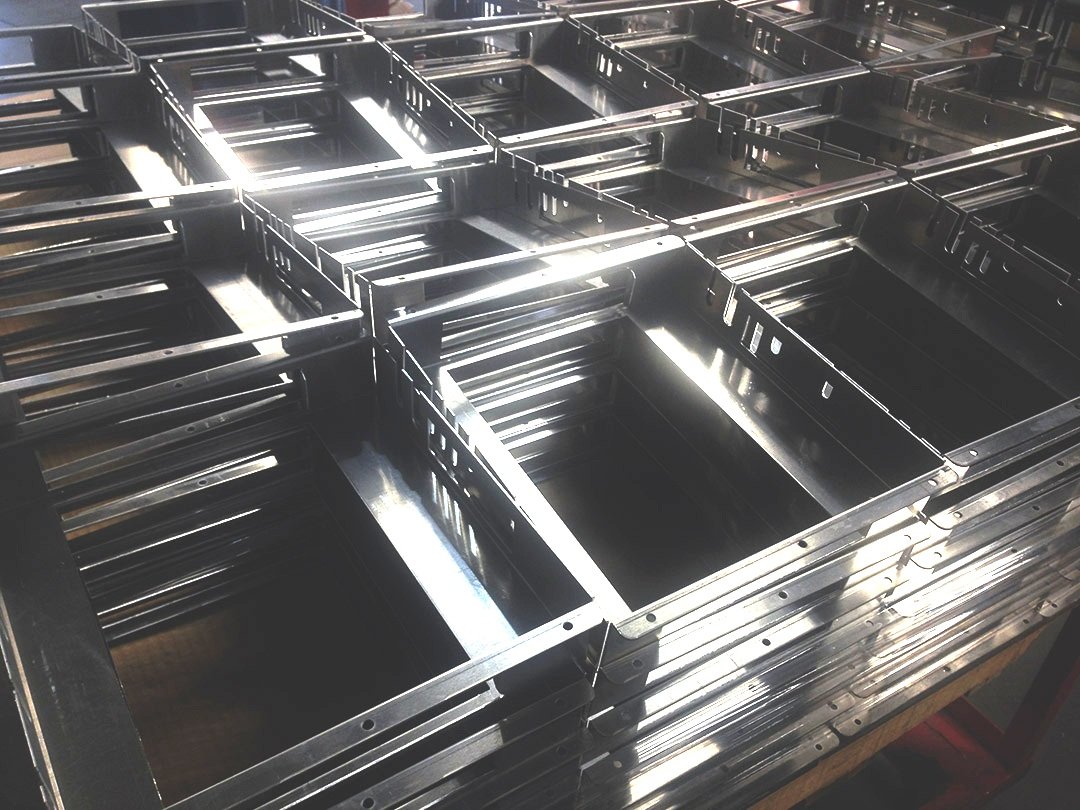

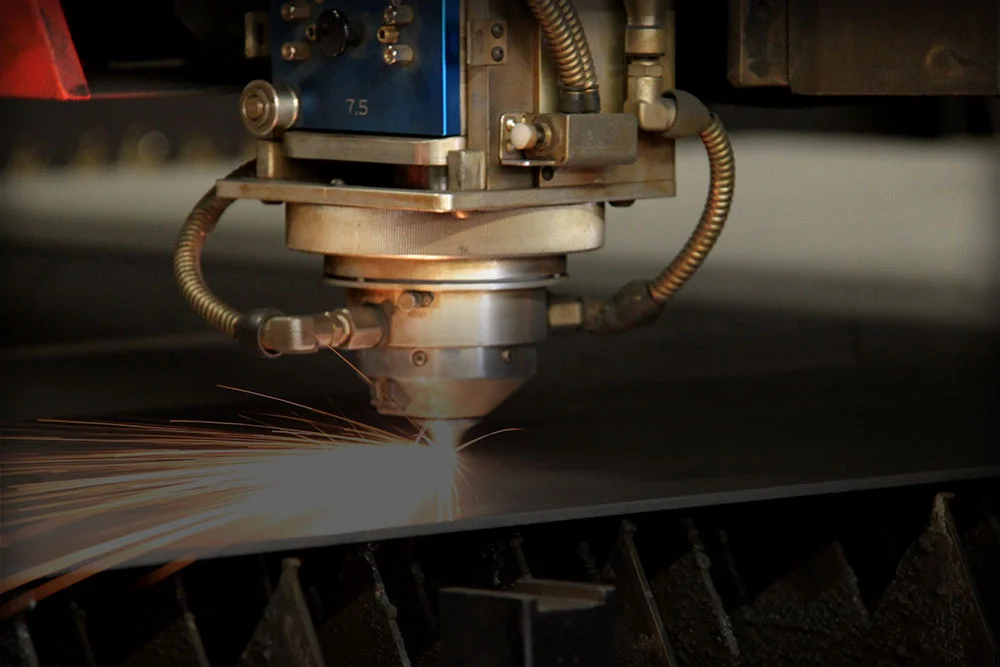

A press brake is a vital tool in the sheet metal fabrication process, used to bend, form, or punch metal with precision and accuracy. This versatile machinery exerts force on a set of dies, utilizing mechanical, hydraulic, electric, or manual means to create a desired shape. While older systems relied on bottom bending or coining techniques, modern press brakes use air bending, resulting in decreased tonnage and more intricate part production.

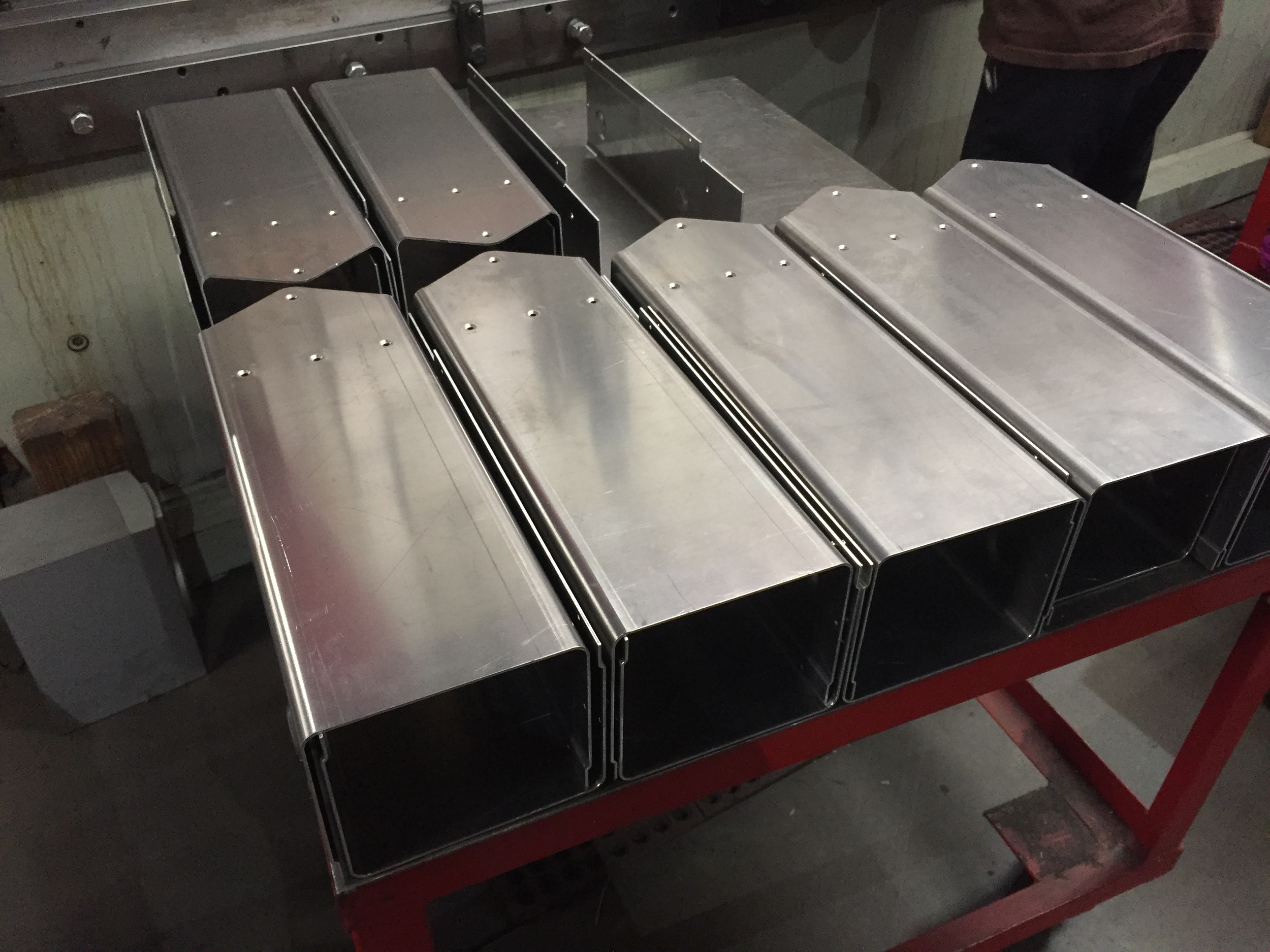

For complex parts, our state-of-the-art precision press brakes are equipped with a unique up-acting design, featuring hydraulic cylinders in the lower beam to match the deflection of the upper beam and eliminate part canoeing. This results in consistent production quality, and a CNC back gauge interface allows for more accurate metal positioning during forming.

At our sheet metal company, we offer high tonnage press brakes with a wide range of capacities, suitable for various materials and production requirements. Trust us to deliver superior results for all your precision sheet metal fabrication needs.

On capabilities

The sheet thickness we typically work with ranges from 0.035” to 0.250”, though we can accommodate thicker or thinner gauges upon request. Our general tolerances are +/- 0.030” for edge to edge, edge to hole, and hole to hole features on single planes or flat parts, and +/- 0.030” for bend to edge/hole features. +/- 1 degree for bend angles. With our commitment to precision, you can trust us to deliver high-quality sheet metal products that meet your specifications.

P: (702) 736-8120

Fax: (702) 736-6169

Email: Sales@rsfab.com